The series launches with the AMCell_small, the first of three standardized cell iterations. AMCell_small is aimed specifically at the academic sector, for schools, universities and company training facilities, through which students can learn the basics of automated polymer, 3D printing.

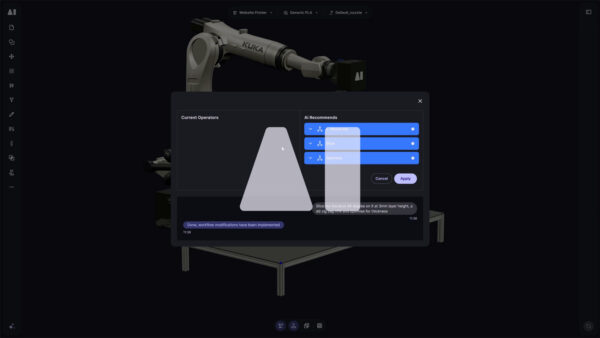

Featuring the KUKA KR AGILUS 10 R900, Ai Build’s additive manufacturing software AiSync, a non-planar extruder head and periphery, AMCell_ has been efficiently and cost effectively packaged to support the optimal delivery of advanced training methods in additive manufacturing principles.

The competent handling of automated, technological products is of paramount importance in practice, in today’s manufacturing environment. The assembly of products is undergoing a revolution, and additive manufacturing is a key driver behind this trend, as it becomes the mass-manufacturing method of choice, as digitally automated workflows replace high volume, serial production techniques.

3D printing is now considered to be a standard part of manufacturers toolkits across industry sectors, such as: automotive, aerospace, marine and energy/power generation, as a cost effective and accelerated alternative to conventional techniques, such as near-net-shape and subtractive manufacturing. Tooling, door handles, dashboards and keels all being produced using 3D printing methods, as manufacturers satisfy both aesthetic and functional considerations.

As demand for additive manufacturing, as a process, has increased, Ai Build has focussed upon the development of its AiSync software that enables the fast, precise and repeatable delivery of, highly efficient, toolpaths using KUKA’s industrial robots. A programme of continuous solution development, that encapsulated machine learning and artificial intelligence, means that today, AiSync customers are able to achieve overall build efficiency gains of a staggering 90% and build failure reductions of 65%.

The AMCell_ series, primarily the next cell generations of _medium and _large shall deliver to manufacturing, in sectors such as automotive and aerospace, a fully autonomous ‘go-to’ solution that will satisfy demand driven additive manufacturing requirements.