Hybrid Manufacturing Software

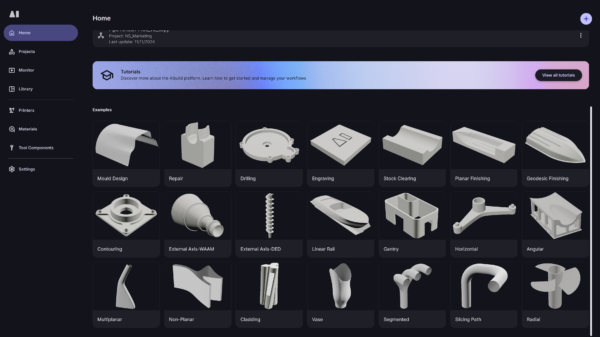

Scale from prototype to production. Aibuild software delivers 3D printing and CNC machining together in one secure platform accessible via direct desktop deployment or a secure cloud connection.

Cloud & Desktop ready.

Aibuild software is available as a stand alone desktop application, or access your work anywhere and collaborate in Aibuild Cloud with no install needed.

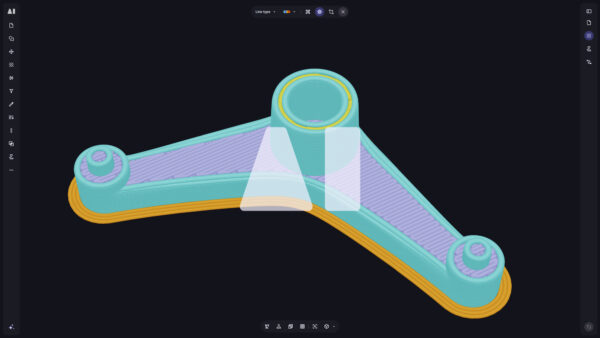

Fully automated toolpath generation for industrial additive manufacturing.

Access example workflows that have been tested and optimised in our R&D Ailab.

All additive manufacturing components – hardware, software, materials – operate as a unified, integrated, intelligent, automated system.

Incorporates end-to-end automation, capturing knowledge and optimal build capacity in the workflow, reusable in subsequent builds.

First time right.

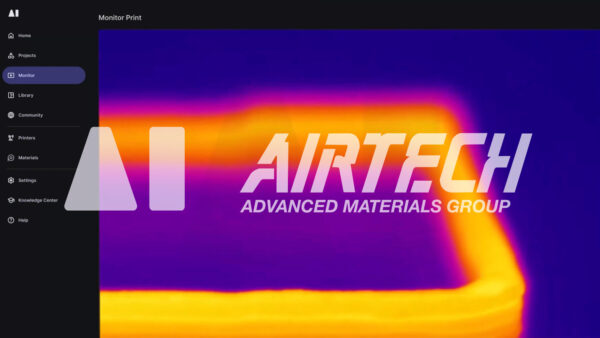

Aibuild accurately predicts the thermal behaviour of a wide range of materials that are physically characterized in our R&D lab. Automatic optimization of process parameters for each material streamlines production, ensuring perfect prints the first time.

Developed and tested by AM experts.

Aibuild is a result of over nine years of intensive, hands-on testing across hardware and material in our London Ailab. We share these experiences and outcomes directly with our clients in the Knowledge Center.

ISO 27001 certified.

ITAR compliant.

The Aibuild Cloud platform is a fully secure, cloud-based solution that offers the entire suite of tools we’ve built over the years to fully customise industrial 3D printing.

Material intelligence

built in.

We work hard with our material partners and hardware vendors to hard code material properties inside our Aibuild additive manufacturing platform. We automatically adjust toolpath generation for specific materials, from concrete to advanced polymers, to high-performance engineering alloys.