OPC-UA is a perfect fit for Industry 4.0, with its design satisfying the demanding requirements of the industrial automation sector. Let us examine some of Industry 4.0’s strictest needs.

Scalability — to unify every device of Industry 4.0, the system must allow for communication between all levels of its hierarchy: from the factory floor, up to the cloud, and at every level in-between.

Previously, industrial systems had a distinct flow. Communication occurred through a multitude of networks at each level of the system. Now, Industry 4.0 promises a decentralised method of communication between all its devices. Through such flexible communication, any component will be able to request information from another regardless of their respective positions within the system. Each device will be able to make use of this information to self-optimise and adapt to its environment. This is a cornerstone of the future of automation.

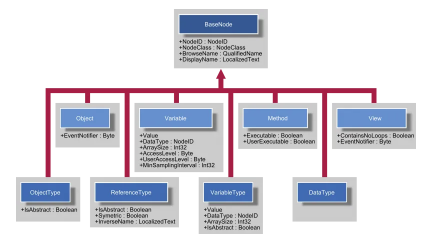

Solving this problem necessitates a consistency in information representation: how else would devices understand one another? As discussed, the OPC-UA information model is used to handle this: simple and complex devices alike can be digitally described in a standardised manner.

Descriptive Modelling — industry is no longer satisfied with the simple transfer of data: it wants its devices to couple this data with detailed information about themselves.

OPC-UA allows for machines to provide additional descriptive information about themselves and the data they share to aid its users in their understanding of the process. OPC-UA’s information model reduces configuration effort, supports quick absorption of information, and allows for simpler machine-to-machine communication.

Independence —the factory floor of the past existed as a hodgepodge of cutting-edge technology intertwined with legacy systems. Industry 4.0 demands that its components are not shackled by vendor dependence.

OPC-UA is platform-independent. It allows for communication between all devices, regardless of their vendor. Additionally, along with the core documents it has published, the OPC Foundation has written an assortment of companion documents that detail how generic systems and components should be implemented across the board. Sharing these templates for data formatting with the market streamlines the process.

Credibility — the nature of industrial systems entails that they must be wary of accepting new technology.

OPC-UA has a rich history, standing proudly on the shoulders of its successful predecessors: OPC classic and COM/DCOM communication. It is a system that has been tried, tested, and improved upon through decades of use. It has earned its reputation as a trustworthy solution.

Security — OPC-UA is secure-by-design. Security is an extremely important consideration, and one worthy of exploring in greater detail within a future blog post.