The way most 3D printing slicing software are experienced by their users can be described as a black box. The usual workflow begins with the users loading their CAD model into the software, entering the desired values for a number of inputs, giving the instruction to the software to slice the model, and finally the software returns the sliced geometry. This process is linear and there is no way to modify the sliced output or fine-tune it. If any changes are required, the only option for the user is to go back to the list of input parameters, modify some values and slice the model from the beginning. If the output is still not as expected, this feedback loop between the sliced model and the values of the input parameters is repeated until the user gets the desired result.

While this workflow offers the advantage of being able to slice a model with minimum effort and technical expertise, its flaws start to show in cases where the user requires increased control over the slicing process. In more advanced workflows, experienced users often try to find ways to hack the software in order to fine-tune the outputs to match the desired output. This means that they have to keep going back to the CAD software and modify the original geometry, export it, load it in the slicer software and slice it again. However, it is more often than not that this design fine-tuning becomes a very lengthy and tedious process that in cases of designing for production it can span weeks of design iterations and sometimes the final output is still not 100% as expected.

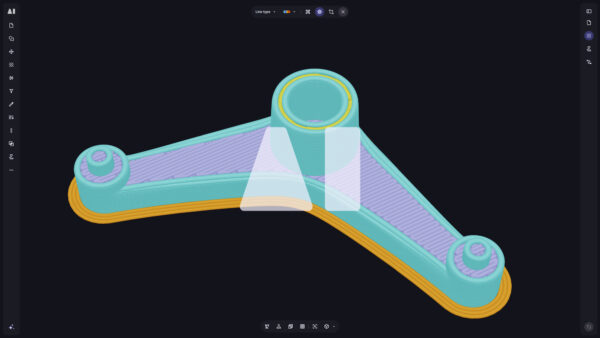

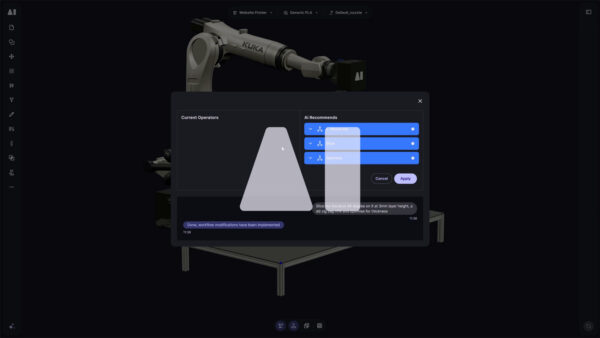

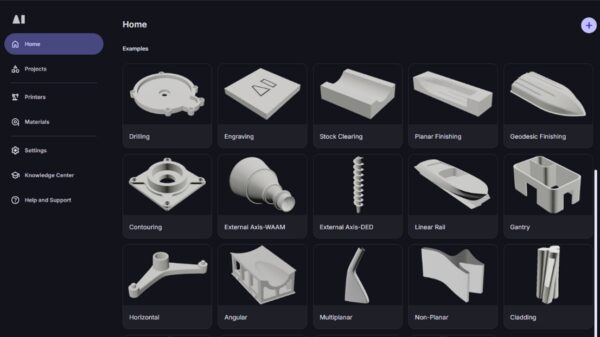

As an alternative to this black box approach, AiSync, Ai Build’s cloud-based platform for large-scale additive manufacturing, handles toolpath generation in a more flexible approach through component-based slicing. Users get access to a powerful engine of components called operators that perform geometric or analytical operations and allow the development of custom workflows based on specific design needs. These workflows are parametric in a form of visual programming with stackable modules for building truly customisable solutions, so they can be easily modified or reused for different designs with similar requirements.

By using this approach, the workflow is not predefined anymore through a fixed amount of inputs and outputs, but the user has the freedom to build their own tools from the bottom-up for each project to best suit the project needs.