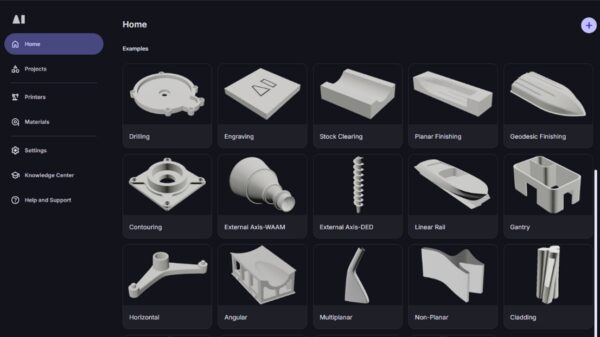

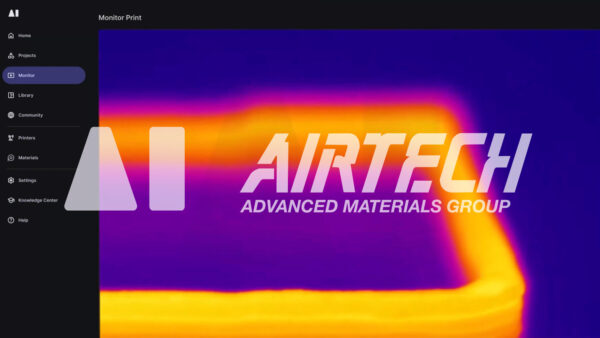

Introducing Slice 2.0, our latest software update, packed with new features to improve your slicing experience. We’ve added special modes tailored for different applications, making sure each one works seamlessly for its use case. Our smart settings now adjust automatically based on real printing tests, saving you time and effort for high quality prints while respecting the nozzle size. Plus, we’ve included new features like segmented printing and cladding to meet all the user needs. Furthermore, we’ve introduced informative cards for each mode, complete with diagrams, detailed explanations, and practical use cases to guide users towards optimal toolpath generation. This update also bolsters computational robustness, addressing bugs, adds requested features, and organises settings into categories for improved usability and enhancing the overall user experience.