Most of us have made a seamless transition to remote working within a few days after the Covid-19 outbreak. Meetings have turned into conference calls, chat rooms have replaced standup conversations and all the other good stuff like virtual happy hours on Friday afternoons.

But what about the factories? Were the manufacturers able to adapt to this new world so quickly as well? Well, not really. Global supply chains have shattered into pieces and almost every manufacturer is in big economic trouble, with the exception of some that produce medical supplies or toilet papers.

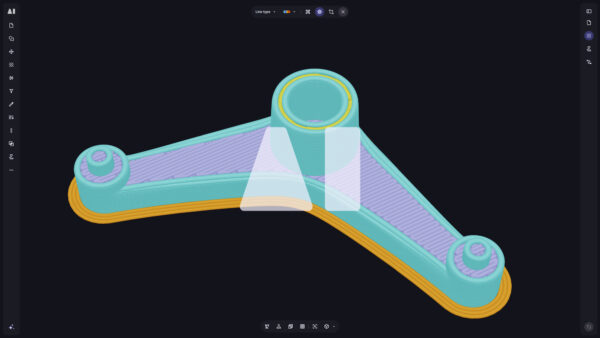

The upside? Covid-19 is a wake up call for the manufacturing industry and we can learn from it. Emergencies fast-forward historic processes as the historian Yuval Harari explained recently. Decisions that in normal times could take years of deliberation are passed in a matter of hours. Makers from all over the world are 3D printing medical supplies now as a response to global shortages and the broken supply chains, such as this startup in Italy, this open-source initiative in Ireland and Volkswagen in Germany.

//

Today is the 11th of March 2025.

Five long years have passed since The World Health Organization declared the Covid-19 outbreak a Pandemic. Remote working is the new normal now. We don’t take cross country flights for drinks and dinners to conduct sales. We are having VR hangouts instead. Yes, the clunky headsets have evolved and finally managed to find their purpose.

This is the world’s first and only Global Remembrance Day. Everyone in every country stays at home for 24 hours to honour the lives of so many people we have lost after the outbreak. Noone works today except the fleets of robots inside dark factories that are starting to appear across different parts of the world. Enter this dark factory at the heart of Shenzhen, China.