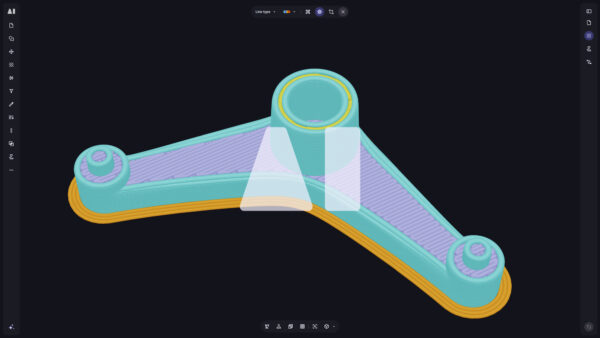

Automatic Angular Slicing Predictor. Finding the optimal slicing plane for a part with overhangs can take over an hour. With part iterations and revised requirements, that can escalate into a lot of wasted engineering time. The new Automatic Angular Slicing Predictor searches, analyzes, and finds the best angular slicing plane, saving up to 60 minutes per part.

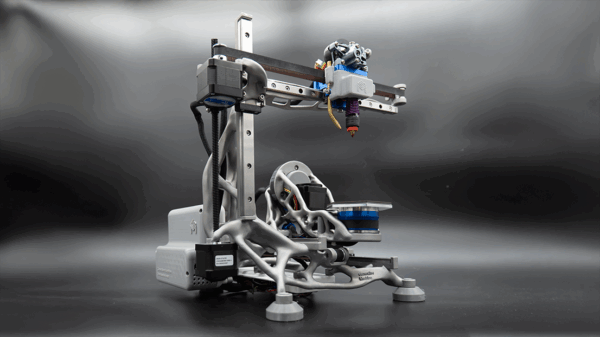

New Example Toolpaths. Getting started has never been easier. Aibuild 3.0 simplifies the process with ready-to-use example toolpaths crafted by our engineers. Find the toolpath that suits your needs, then copy and adapt it to match your specific requirements. Choose your file, printer, and material, and the intelligent parametric workflow will automatically adjust deposition parameters to fit your configuration. Make any necessary edits, simulate the toolpath, and print your part quickly and easily.

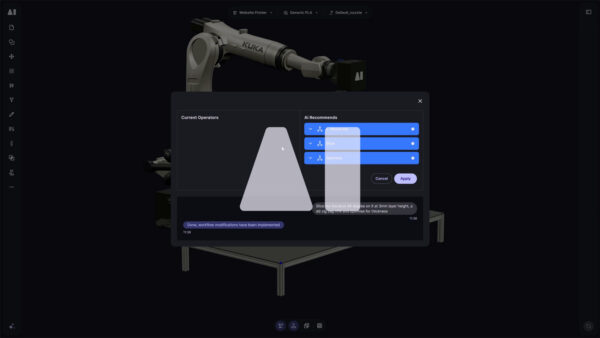

Project Sharing. Successful builds depend on efficient communication and data sharing. Our users collaborate with various stakeholders, including material suppliers, machine OEMs, integrators, and researchers. With Aibuild 3.0, you can now share projects with other organizations, maintaining control over the files and data you share. This streamlined sharing process accelerates printing and fosters stronger partnerships with clients and collaborators.