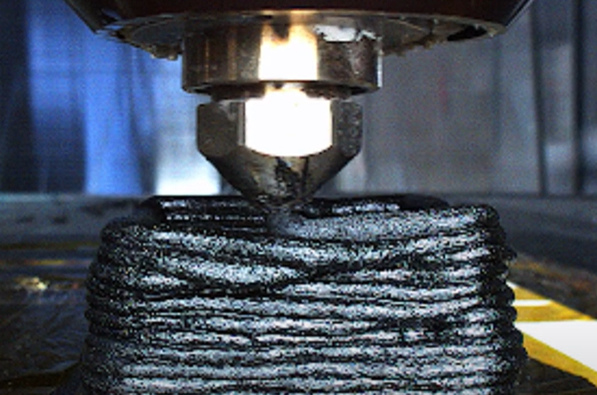

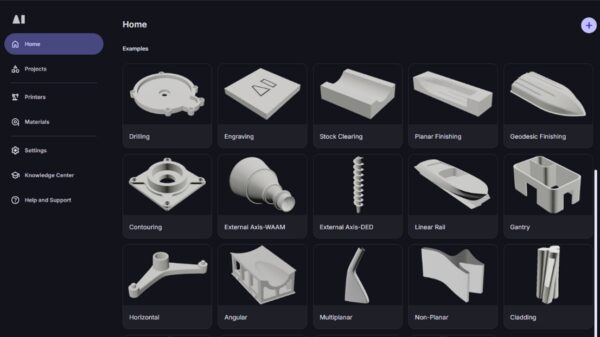

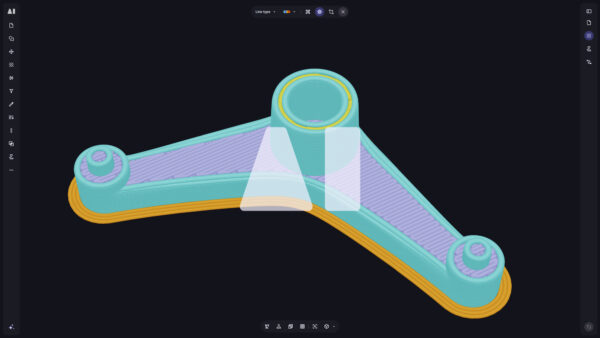

If you have ever watched a 20-hour large-format additive build slump into a shiny puddle or fracture on the very next layer, you already know the villain: uncontrolled heat. In metal and polymer LFAM, interpass temperature rules everything. Too hot, the bead sags; too cold, it cracks – and either way the mechanical properties suffer. Our team has spent the past 6 months turning that pain point into a predictable, GPU-accelerated workflow, and today we’re beta releasing the industry’s first finite-element (FE) thermal simulator baked directly into a CAM toolpathing engine.