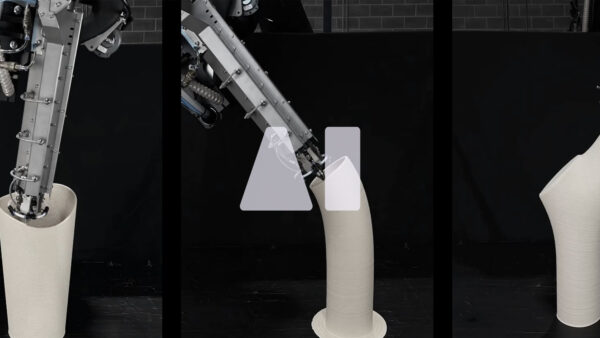

In response to the automotive industry’s shift toward larger and heavier body panels, driven by megacasting and increased CFRP structures, Aibuild undertook a significant challenge. Tasked by a Global Automotive Brand, they sought to revolutionize the pick-and-placement process using 3D-printed polymer grippers produced in-house.

The existing gripper systems, reliant on standard metal struts, posed issues of high part count, weight, and cost as well as long lead times. The unique power of Aibuild’s software, integrated with a multi-axis printer, allowed for the creation of complex structures without support, reducing time and waste.